rockwell c hardness testing on thin substrates|rockwell hardness c scale chart : export Rockwell Hardness Test. The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a . WEB12 de jan. de 2024 · Find the latest job opportunities in Bangladesh. Search and apply for jobs in various industries, including IT, finance, marketing, and more. Connect with top .

{plog:ftitle_list}

WEBO site da Tucano Bet é apenas mais um entre as inúmeras Casas de Apostas e Casinos Online como a zz777, 955Bet e 5Gbet.Por se tratar de um site ilegal, o design e os .

A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The Rockwell test is applicable to a wide range of part sizes.The Rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. These materials often have high hardness levels and require higher applied loads to .

rockwell hardness testing procedure pdf

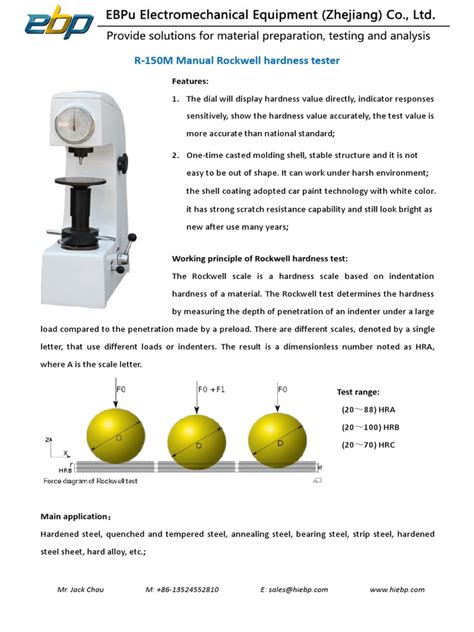

[Insert image here: A diagram illustrating a Rockwell hardness test setup, showing the indenter, the major and minor loads, and a sample with sufficient thickness.] Example: A thin sheet .Rockwell Hardness Test. The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a . Foremost to any Rockwell test process is identification of the proper hardness scale to be used on the component to be tested. There are 30 different Rockwell scales with the majority of applications covered by the .The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously .

The Rockwell C scale is used for determining the hardness of hard steels. A conical diamond indentor is employed, called a brale, under a 150 Kg load. The Rockwell B test applies a 100 .

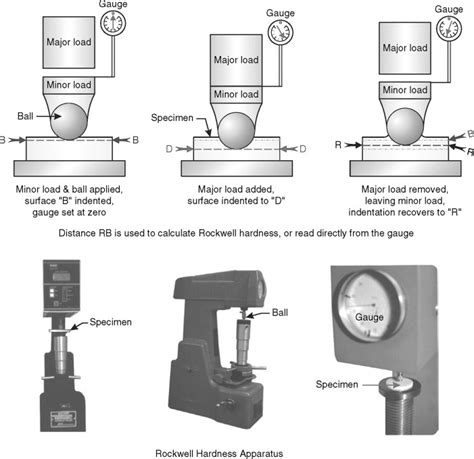

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .Find the minimum thickness for regular Rockwell or superficial Rockwell testing here. Download as PDF or get the thickness in inches or mm right away. ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . ideal for quick, high-volume testing, the Vickers method excels in testing very small or thin specimens and provides detailed microhardness data. This makes it .

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic Scales The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels. The effective half-apex angle of Berkovich indenter is 70.3°, which is larger than the half-apex angle (i.e., 60°) of Rockwell C indenter, and thus, it is the blunt tip of Rockwell C indenter .

In the Rockwell hardness test, an indenter is pressed into the material. . However, especially when testing thin sheets, there is a risk that the material will only bulged out on the opposite side due to the high test force and thus falsify the measurement result. For this reason, variant A was introduced for diamond cone testing, which .one standard deviation. The copper films are soft in comparison with the oxidised silicon substrate, which has a hardness of 12–13 GPa. For the thinnest films at the highest applied loads the hardness is equal to the substrate hardness, indicating that the substrate is dominating the hardness behaviour being obtained.These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table Hardness is defined as the resistance of a material against local deformation. 1 The indentation hardness test is the most widely used technique for hardness measurement. 2,3 In indentation tests, an indenter penetrates into the surface of a material under a compressive load in a normal direction and forms a permanent indentation. The hardness value is .

The hardness of samples was assessed by the Vickers indentation (TriboScope, 500 µN loads, 5 s, ASTM C 1327–03). Adhesion of the coatings was evaluated by a Rockwell C hardness apparatus (15 kg, VDI 3198 standard) . The microstructures of the polished coatings were observed by field emission scanning electron microscopy (FESEM, TESCAN MIRA3 .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the information CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. . Rebound type testers are NOT suitable for thin light weight parts like sheet metal, knives, bolts, nuts, washers etc. . For the majority of your hardness testing requirements. Use .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.Fig 1: Rockwell Hardness Test Machine Schematic [9] RHT uses the Rockwell scale, shown in Table 1, to . cemented carbides, thin steel, and shallow case-hardened steel

Rockwell Hardness Testing Reference Guide Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

rockwell hardness testing procedure

high-speed steel substrate W 6Mo 5Cr 4V 2 (M2) by the phy-sical vapor deposition technology. The hardness test, scratch test, Rockwell adhesion test, and pin -on-disc (POD) wear test were carried out aiming to investigate the per-formances of the three coatings includinghardness, adhe-sion strength, and wear resistance. The results show thatHardness testing of thin metal sheets and wires / Hardness testing of casts, flanges, shafts, and bars/pipes / Quality and wear control of turbine blades and brake systems. Contact us now . The Portable Rockwell metal hardness tester is based, as its name suggests, on the static Rockwell measuring principle where the penetration depths under . The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .

Portable Hardness Testing Leeb – Rockwell – UCI Interactive ASTM DIN EN ISO GB/T JB/T . coatings, thin or impact-sen-sitive parts. Test blocks <500 HLD ~600 HLD ~775 HLD <710 HLDL ~780 HLDL ~890 HLDL <815 HLS ~875 HLS ~740 HLE ~810 HLE . Hardness Testing Equotip .Rockwell Hardness Testing Machine: Comes in different scales (A, B, C, etc.) to match various hardness levels and types of materials. Indenter: Usually, a diamond cone or hardened steel ball is selected according to the material under examination. Test specimen: the material or component undergoing evaluation. Methodology: Steps: 1.The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; Why Choose Us; Testing Types. Hardness Testing Basics . thin steel, and shallow case-hardened steel. B. 100 kgf. 1/16″ WC Ball. Copper alloys, soft .

pcr analyzer lab equipment

rockwell hardness testing pdf

WEBAs contas ou partidas bloqueadas não são incluídas na emissão de advertências e são impressas em uma lista de exceções com o motivo do bloqueio. Nível de advertência. .

rockwell c hardness testing on thin substrates|rockwell hardness c scale chart